Fabric cost

depending on whether you choose standard, specialty, or sustainable fabrics

depending on whether you choose standard, specialty, or sustainable fabrics

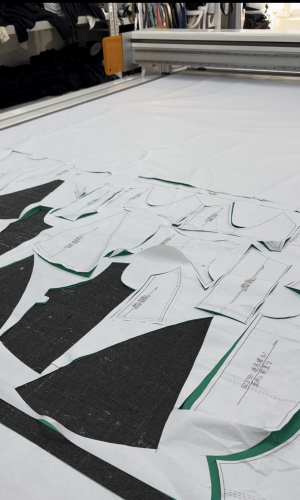

influenced by design complexity, material sourcing, and specific manufacturing techniques

we offer free design support or provide access to our original design library for your selection

A reliable manufacturer should have stable material sourcing, with options for functional and sustainable fabrics.Bloomto partners with 50+ certified fabric suppliers to ensure consistent quality and diverse material choices.

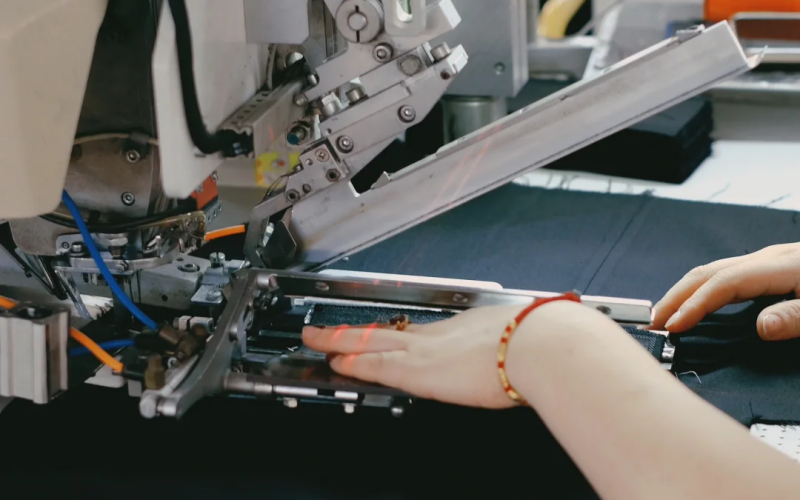

Strong quality control processes, including fabric inspections, garment testing, and third-party certifications. Bloomto has an in-house QC team with full-process inspections to guarantee international standards.

Flexibility to support both small MOQs and large-scale orders, with dependable lead times.Bloomto delivers over 500,000 pieces per month and supports both quick replenishment and bulk production.

Clear and timely communication with dedicated support throughout the order process. Bloomto assigns a project manager for every order, ensuring transparent updates and quick responses.

Ability to provide design support and fabric innovation to strengthen brand competitiveness. BloomTo owns an in-house fabric R&D lab and original design library, helping brands stay differentiated.

Proven experience with successful collaborations across different brand stages.Bloomto has supported both emerging and established brands worldwide, earning long-term trust.

Bloomto has over 10 years of expertise in activewear manufacturing, offering one-stop private label services for custom yoga wear, sports bras, leggings, and fitness sets. From concept to delivery, we help emerging and established brands bring their vision to life.